The company has a number of advanced production equipment and high-quality technicians,

to ensure the production capacity of powerful enterprises, to deliver quality products to customers in time,

and meet customer needs.

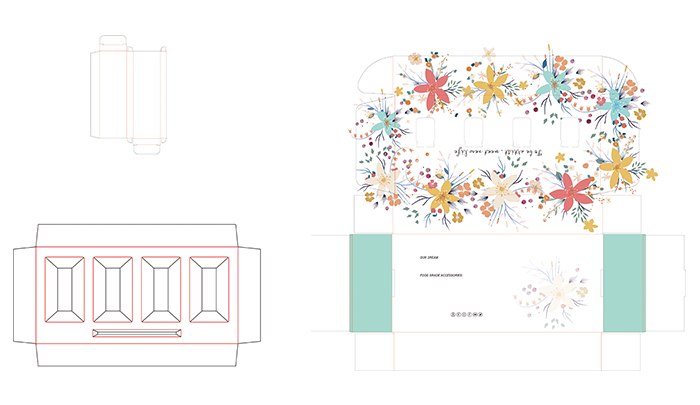

We get the drawings or samples from customers. Or we charge for investigation, and collecting market data.

We will draw the 3D drawings according to the customers' 2D drawings or samples, and send the 3D appearance mock-up effect to customers for confirmation.

When getting confirmation from a customer, we will make 3D mock-up sample to confirm again. If all drawings are ready from customer, we can directly quote asap.

When the customer confirms the mock-up sample, do the structure exactly, and issue the final drawing file to the auditor quotation;

According to customer's requirements of mold material, product material/quality/order quantity, accounting mould charge and product price, send to customer for confirmation.

We will make mould after getting the mold orders or product order from the customers after get the mould charge.

We will make real TN samples after the mould ready and send to customers for confirmation.

Trial production after the customer confirmed the pre-production sample. After getting the product order, we started trial production, to find the problems in the production process and made adjustments.

We will produce the products after getting the customers' confirmation.

We will inspect the products by our inspectors or ask the customers to inspect together with us when finished.

We will ship the goods to the customers after getting the inspection result ok and the customers' confirmation.

Customised color, As pantone number "c"or 'u'. 13 years of OEM management experience in American brands.

Free custom samples for you, Silk screen printing/laser etching/heat transfer/3D printing.

We can do customized logo by laser engraving, silk screen painting, heat transfer painting, etc., Ploybag+white box+master carton,

color box(as customized design) tube box or CDU, etc.

Technical drawing suction cup behavior-driven development vacuum cup and mug.

We can do customized Spray painting; Powder Coating; Water transfer printing; Gas transfer printing;

Heat transfer printing; electroplate 3Dpainting etc.

We take the lead in 6 automatic metalworking production lines and 3 automatic spraying lines. The daily production capacity of accessories workshops such as bottle caps and bottle bottom reaches more than 100,000 pieces. In addition, we use automatic pipe drawing machine in the factory to ensure that the roundness and straightness of stainless steel pipe, wire drawing, wheel printing, internal and external welds are up to standard.

The next big idea can come from anywhere, at any time.

We use first- and third-party cookies including other tracking technologies from third party publishers to give you the full functionality of our website, to customize your user experience, perform analytics and deliver personalized advertising on our websites, apps and newsletters across internet and via social media platforms. For that purpose, we collect information about user, browsing patterns and device.

By clicking "Accept All Cookies", you accept this, and agree that we share this information with third parties, such as our advertising partners. If you prefer, you can choose to continue with "Only Required Cookies". But keep in mind that blocking some types of cookies may impact how we can deliver tailored content that you might like.

For more information and to customize your options, click on "Cookie settings". If you want to learn more about cookies and why we use them, visit our Cookie Policy page at any time. Cookie Policy